CHECK OUT MY

PORTFOLIO

Medical 3D-printing

During my studies, I worked on a project together with the company HealthPrint with the aim to optimize the usage of 3D printers in terms of customization for prosthetics, implants, and anatomical models. This technology enabled the development of customized and precise solutions for patient care, with future potential to transform healthcare through faster production, cost reduction, and personalized treatment options tailored to individual patients.

Result

- Implemented a scanner to efficiently create customized prosthetics, with great success.

Challenges

- The need for regulatory approval and standardization. To overcome this, we collaborated with regulatory agencies.

Learnings

- Practical experience in areas such as design, engineering related to health care and 3D-printing technology.

Recycle metal waste

This project aimed to explore and develop new approaches to effectively recycle metal waste materials generated in the university metal workshop.

By focusing on sustainability and resource optimization, the goal was to minimize the environmental impact associated with metal waste disposal and contribute to a circular economy within the workshop's operations.

Result

A collaboration with the local recycling center resulted in the achievement that 97% of all scrap metal can now be recycled.

Challenges

Conducting a thorough waste sorting was time-consuming and complex, but we solved it by utilizing the latest technology.

Learnings

I gained deeper knowledge about the circular economy and waste management, which is crucial when developing products.

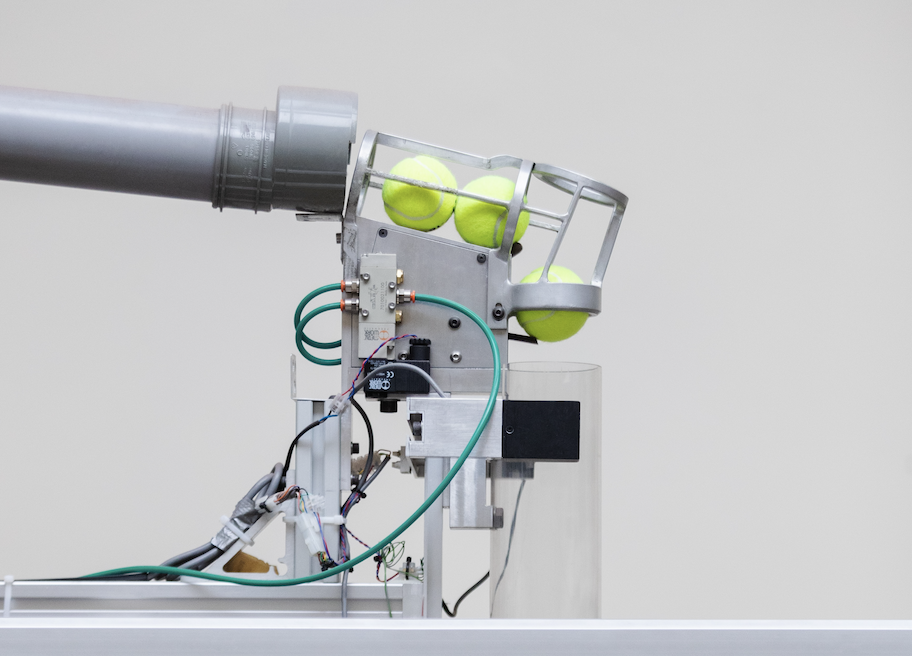

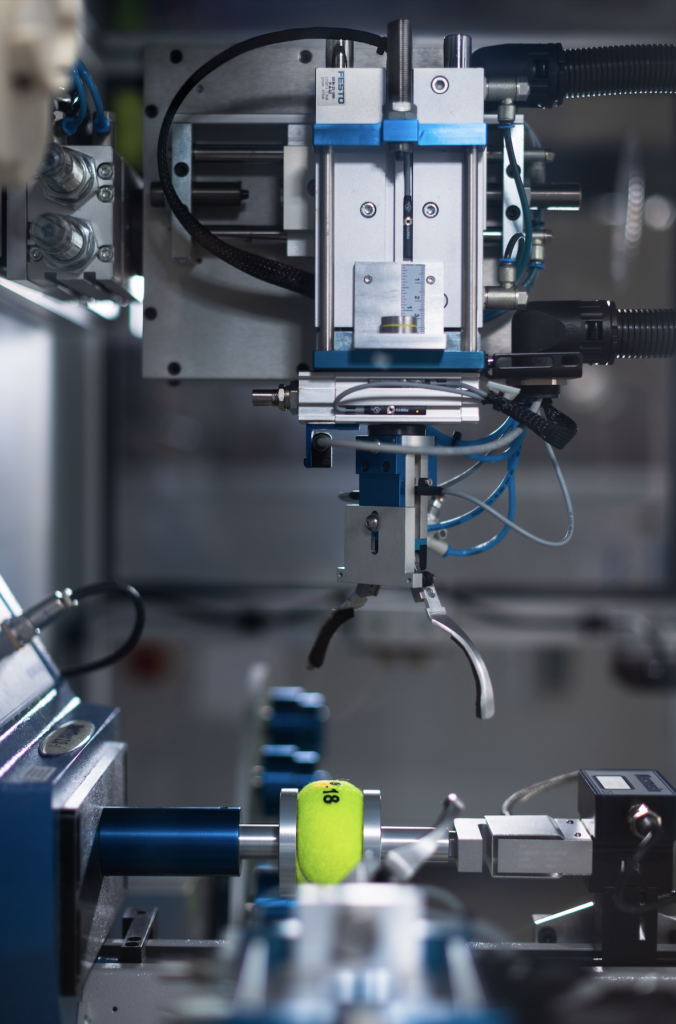

Optimize operation flow

Introducing a new robotic system to optimize the flow of operations within the logistics company FastPack. By leveraging automation and advanced robotics technology, the goal was to enhance efficiency, accuracy, and productivity in various aspects of the company’s logistics processes.

Result

- We achieved a 40% increase in flow efficiency by automating tasks such as order picking, sorting, and inventory management.

Challenges

- Through effective collaboration with experts, the implementation was streamlined despite its inherent technical complexity.

Learnings

- This project bridged the gap between theoretical knowledge and practical application, providing valuable insights into programming and robot installation.

Project movie

Check out the results from optimizing the operation flow.